No dew? No problem.

- Overview

- How it Works

- Benefits

- Payback Calculator

- Testimonials

- Videos

- Pricing and Information

- Literature

- FAQs

Welcome to Harvest Tec's Dew Simulator, where adding moisture to your hay Began!

Harvest Tec invented the original system for softening your forage crop with moisture starting in 2001!!

| Waiting for natural dew to soften alfalfa before baling is a challenge for producers in arid areas. Many producers have tried to spray over the windrow to bring the moisture content up, only to find that just the top of the windrow becomes soft, but the leaves still shatter off most of the hay.

The Next Generation of Dew Simulator is Here! Harvest Tec is proud to announce the Launch of the HydroBale! |

Ideal Moisture | The newly redesigned Dew Simulator allows for the precise addition of water to windrowed alfalfa. The windrow will be as soft as if it had just received the ideal amount of dew. By spraying into the windrow prior to baling, moisture is added to all of the plant material. The water softens the hay, giving the hay the appearance and test of hay made with natural dew. |

||

Control Your Time | Become more efficient with the Dew Simulator by opening your baling window throughout early morning and later evenings when operating conditions become a challenge. Take more control and become more productive baling on your schedule |

||

|

|

||

The NumbersEconomic Summary Study - Earl Creech & Ryan Larsen Utah State University Annualized Cost of Ownership $14,608 Total Cost $21,675 That's an additional $16,280! |

||

|

|

Specifications

|

Benefits of the Dew SimulatorThe Dew Simulator is designed to re-hydrate dry alfalfa windrows from 6-10% moisture back up to 14-16% moisture in dry, arid climates that don’t see a lot of natural moisture and have to rely on the dew. By adding the moisture back into the windrow before baling, operators have the ability to open up their baling window, bale longer hours, and make better quality alfalfa bales. |

|

Please request more info or contact Harvest Tec today!

800.635.7468

How it works

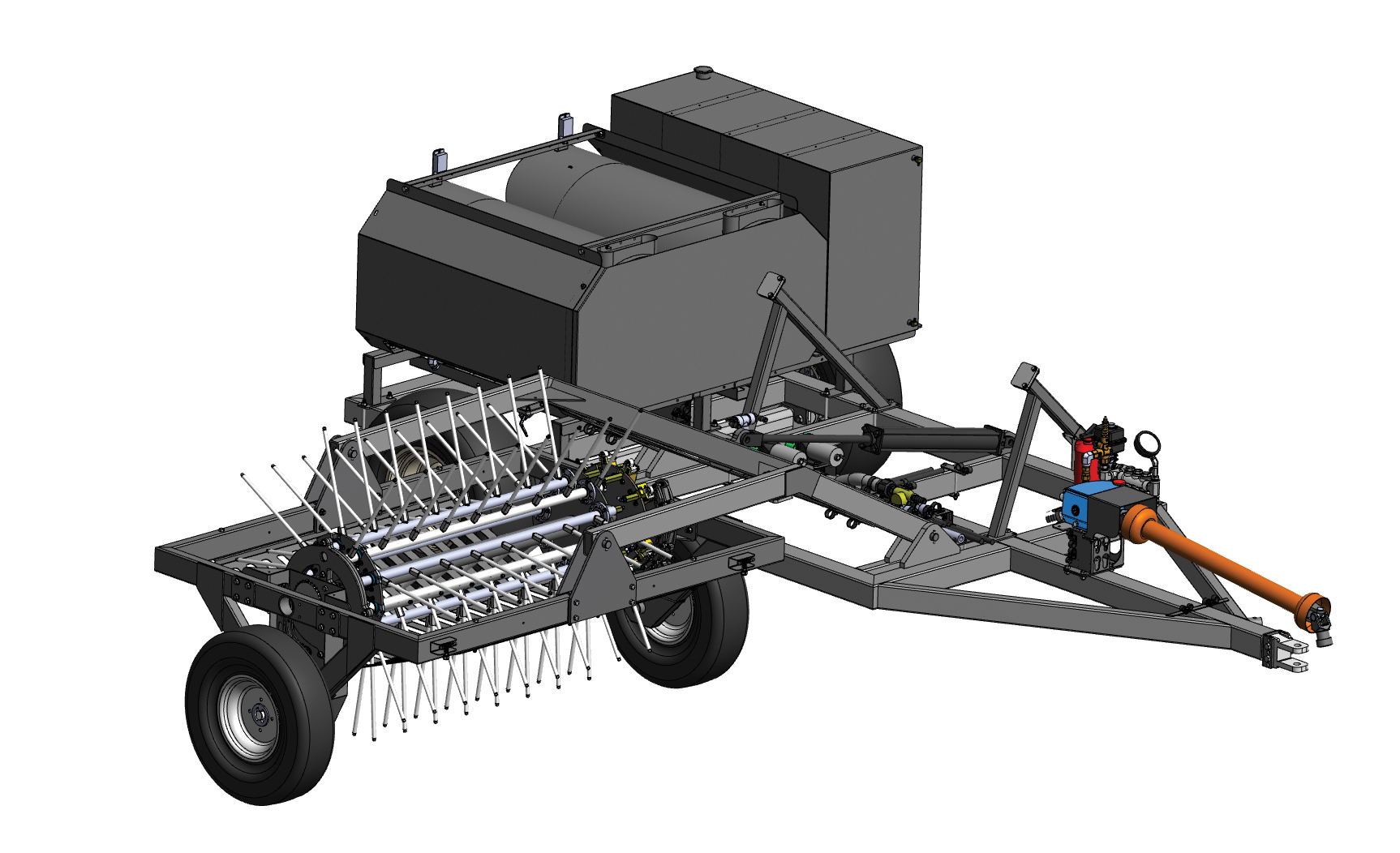

The Dew Simulator runs as a separate pass before baling, and the machine preheats water to 240°F, and applies the hot mist to the windrow via a reel with tines that enter into the windrow and spray from the bottom of the windrow up, the same way that natural dew occurs in windrowed alfalfa. The heated water has been shown to soften the plant’s material more effectively than cold water, allowing the crop to retain more leaves.

What it does

- Water is pre-heated to a target temperature of 240°F

- 65 tine (85 tine option) cam reel enters and exits the windrow vertically, with no crop disturbance

- Valve actuated tine rows only apply high pressure spray when inside the windrow

- Valve actuator adjustable for windrow height

- Valve actuation can be turned off for windrows with bottom moisture

- 250-500 psi spray delivers fine droplets between 20 and 40 microns

- 1% of a specially formulated surfactant added at a cost of $2/ton (10 gal per 1000 gal water)

Specifications

- Reel wing lowers to the right of the main chassis

- Water tank is operator supplied to be pulled directly behind (1000 gallons recommended and will treat 80 tons)

- PTO driven pump runs on 1000 rpm to deliver 15 gpm@750 psi

- 2 in-series diesel fuel water heaters deliver 750,000 BTU each for total of 1,500,000 to raise water temperature 180°F at 18 gpm

- Water heaters use 5-11 gallons per hour of #2 diesel during operation

- 70-100 HP tractor recommended

Operator Adjustments

- Operation speeds between 2 and 10 mph to be matched to speed of baling

- Water delivery of 10 to 18 gallons per ton depending on how dry the hay is

- Treatment width is adjustable between 40 and 59 inches

- Treatment height is adjustable between 8 and 20 inches

- Tip selection is matched to treating/baling speed (10-60 tons per hour covered by 3 tip sets)

Re-hydrating windrows within seconds of baling in high evaporation conditions

Benefits of the Dew Simulator

The Model 720 Dew Simulator is designed to re-hydrate dry alfalfa windrows from 6-10% moisture back up to 14-16% moisture in dry, arid climates that don’t see a lot of natural moisture and have to rely on the dew. By adding the moisture back into the windrow before baling, operators have the ability to open up their baling window, bale longer hours, and make better quality alfalfa bales.

Weight Gain from Reduced Leaf Loss

Total Tons Treated 1000 tons

Reduced Leaf Shatter by Adding 4 Points of Moisture¹ 4%

Increase in Tonnage from Less Leaf Shatter 40 tons

Weight Gain from Additional 4 Points of Moisture Added

Total Tons Treated 1000 tons

Weight of Additional Water per Ton (lbs/ton) 4%

Increase in Tonnage from Additional Water 40 tons

Total Tons Added 80

Value per Ton $180

Total Value Added $14,400

¹Based on laboratory study on alfalfa in a vibration chamber at different moistures conducted by the University of Manitoba in cooperation with Colorado State University.

Payback Calculator

The Model 720 is an investment to your operation that can increase efficiency and value to an operation. How about to your specific operation? Click on the Payback Calculator link below to see how the Model 720 Dew Simulator can bring value to your farm.

Model 720 Dew Simulator Payback Calculator

Utah State University ROI Calculator Comparing Dew Simulator to Staheli West Steamer

Testimonials

‘The biggest factor for us is that we can go out and rake in the morning. Keep all the leaves on with a nice dew and we can then wait for it to get really hot and dry and go out at 12-1pm with a Dew Simulator and go until 5 or 6pm and not have to go all night. It’s going to be more efficient for our production, getting the quality of hay they (customers) want’.

‘With the Dew Simualtor it sets us apart from a lot of people. And with Gary and Steve staying at the forefront of technology and incorporating the Dew Simualtor into our game, it doesn’t get much better’.

Steve Johnson, Gary Frank & Cliff Dawson of Dakota Hay Service – Burton, TX

Click HERE to see the full testimonial!

‘Just the other day we were right at the perfect dew point, just about to put us over the edge to where we could bale. But it just wasn’t enough. We were able to fire off the dew machine and we baled 60 acres that morning that otherwise would have laid there until the next day, or two days, whenever we got a natural dew’.

‘I think it’s a tool that anybody that’s putting up commercial hay or just trying to put up high quality hay on any sort of larger scale, it can definitely help’.

Sam Nordick, Nebraska

Click HERE to see the full testimonial

‘This is our first year with the machine and to be honest, we’ve used it every cutting, every field, every time. It helps with us on our window of being able to bale. We can start a little bit before the dew comes in or if there is a storm approaching, we begin baling right then and there.’

‘About 1/3 of our hay goes to local cattlemen. And they want to see a nice tight bale. With the dew simulator you can get a better pack, better stroke, better flake, and make a tighter and fuller bale with better bale weights.’

David Andrade, Utah

Click Here to see the full testimonial!

“With the Dew Simulator you can get moisture in the bottom of the windrow, and you can soften the windrow and lot quicker. I try to bale really close behind the machine, and it’s making really nice hay. It opens the window for baling. I baled hay at 8 o’clock in the evening the other night trying to see if I could make it work, and it made good hay.”

Colin Bowler, Utah

Click HERE to see the full testimonial!

“We start adding dew with the Dew Simulator and we can bring our moisture back up to 15-16% moisture, and our bales will weigh at least a hundred pounds more. The leaves are going into the bale and not only increasing weight, but the quality of the bale of alfalfa as well.”

Jim and Doug Kizzire, Nebraska

“This process has allowed us to put up large quantities of supreme dairy quality hay; not only put it up, but put it up on our own schedule, without baling through the night. It is a lot less effort and we put up a lot more hay. We actually put up 360 acres in one day, using the Dew Simulator and running two balers.”

Rusty Lytle, South Dakota

Click HERE for an article featuring the Lytle’s hay operation published in the Hay & Forage Grower magazine in January, 2019

We’re seeing better yields, our tests are equal to hay put up with natural dew and in some cases even better depending on the field. Overall it has really changed the way we’ve run our production”.

Kurt Bohrer, Wyoming

Click HERE to see the full testimonial!

“With the dew simulator we can actually control exactly what we want as far as moisture level in the bale. Typically we like to bale with the Dew Simulator and bale through an entire day. We don’t just shoot for a two hour target of time. We shoot for a target moisture and bale all day.”

Gale Carr, Fort Hancock, TX

Click Here to see the full testimonial!

“We got the Dew Simulator to try and make the guessing game of how to get the dew manageable, because high quality hay comes at a price. It has to be baled at the right moisture to get the leaves in there, and you get the higher protein. “

Thomas Whittle, Gooding, ID

Click Here to see the full testimonial!

“You can go from knocking leaf off like crazy to just incredible leaf retention, you’re retaining all leaf. It’s a definite improvement on our operation by far.”

Nick Lettunich, Fabens, TX

Click HERE to see the full testimonial!

“The dew simulator has brought the quality of the small square bales up tremendously. We can now put the dew moisture on ourselves and make a better product”.

Fred McMinn, New Mexico

Click HERE to see the full testimonial!

How Does the Harvest Tec 720 Dew Simulator Work? |

Harvest Tec Model 720 Dew Simulator Animation |

Harvest Tec Model 720 Dew Simulator Introductory Video |

Harvest Tec Model 720 Dew Simulator Walk-Around |

Dew Simulator Field Footage - 720 Dew Simulator |

Small Square Bales and the 720 Dew Simulator |

Dew Simulator Monitor and Setup |

|

Service Videos |

|

Remove Igniter from Burner - 720 Dew Simulator Service |

Reinstall Igniter from Burner - 720 Dew Simulator Service |

Adjust Electrodes on Igniter - 720 Dew Simulator Service |

Adjust Air Bands for Clean Burn- 720 Dew Simulator Service |

Remove and Install Reel Hoses |

Dew Simulator Valve Roller Rebuild |

Dew Simulator Winterization |

|

Click on the links below for more information

Model 721 Dew Simulator Brochure

ERADI(Ca)TE Plus - Water Conditioner

ERADI(Ca)TE Plus - MSDS

Enhancing Hay Quality for Farmers Using an Artificial Dew System During the Raking Process

University of Utah study:

Comparison of Strategies to Remoisturize Alfalfa in the Windrow for Baling

Commonly asked questions about the 720 Dew Simulator

What size tractor is needed?

Size is not important, simply need 1000RPM PTO and preferably 10,000 lbs in weight. May need heavier tractor if baling in hills. Dew Sim + 1000 gal water tank will be about 15,000 lbs pushing tractor down a hill.

How long do you wait to bale?

All dependent on evaporation conditions. Excessive heat (90 deg or more) or excessive wind (10mph or more) will usually lead to baling within seconds. If calm evening after sun goes down a grower would ideally wait 15 min allowing windrows to soften even more.

How many acres will 1000 gallons treat?

This is all dependent on amount of moisture in windrow. 1000 gallons typically treats 30 to 50 tons before needing to refill. Raising from 6% windrow requires more water than raising from 11% windrow.

Any special water requirements?

We want clean water to avoid plugging of filters/tips. 2 filters on unit. If really hard water we recommend an additive to keep minerals in suspension in water to pass thru tips. Surfactant is optional but can also improve dispersing of water droplet across plant material for better penetration and softening.

The Surfactant that is recommended to use is ERADI(Ca)TE Plus

How do you know how much water to apply?

Guidelines are provided for setting pressure for flow rate but this is a minor learning curve. It is critical dew sim operator is speaking w baler operator throughout baling. The baler operator should be looking for baler pressures similar to ideal dew conditions.

Is it applying steam?

No, we do not have a boiler but rather use water heaters. We are under pressure (400 to 1100 psi) so we are simply applying a “heated mist”.

How fast can you apply?

Dew sim should always travel same speed as 1 big baler or twice the speed of 2 small square balers. If baling at 12mph the dew sim can treat at 12mph.

Can you bale all day with this unit?

Quality is always jeopardized in the middle of the summer in the heat of the summer. The unit is meant to extend baling window a few hours before dew sets in and a few hours after dew burns off. If the dew doesn't come in, just keep going.