- Large Square

- Small Square

- Round

- Controls

- Hay Preservative

- Accessories

- Brochures & Manuals

- Selection Guide

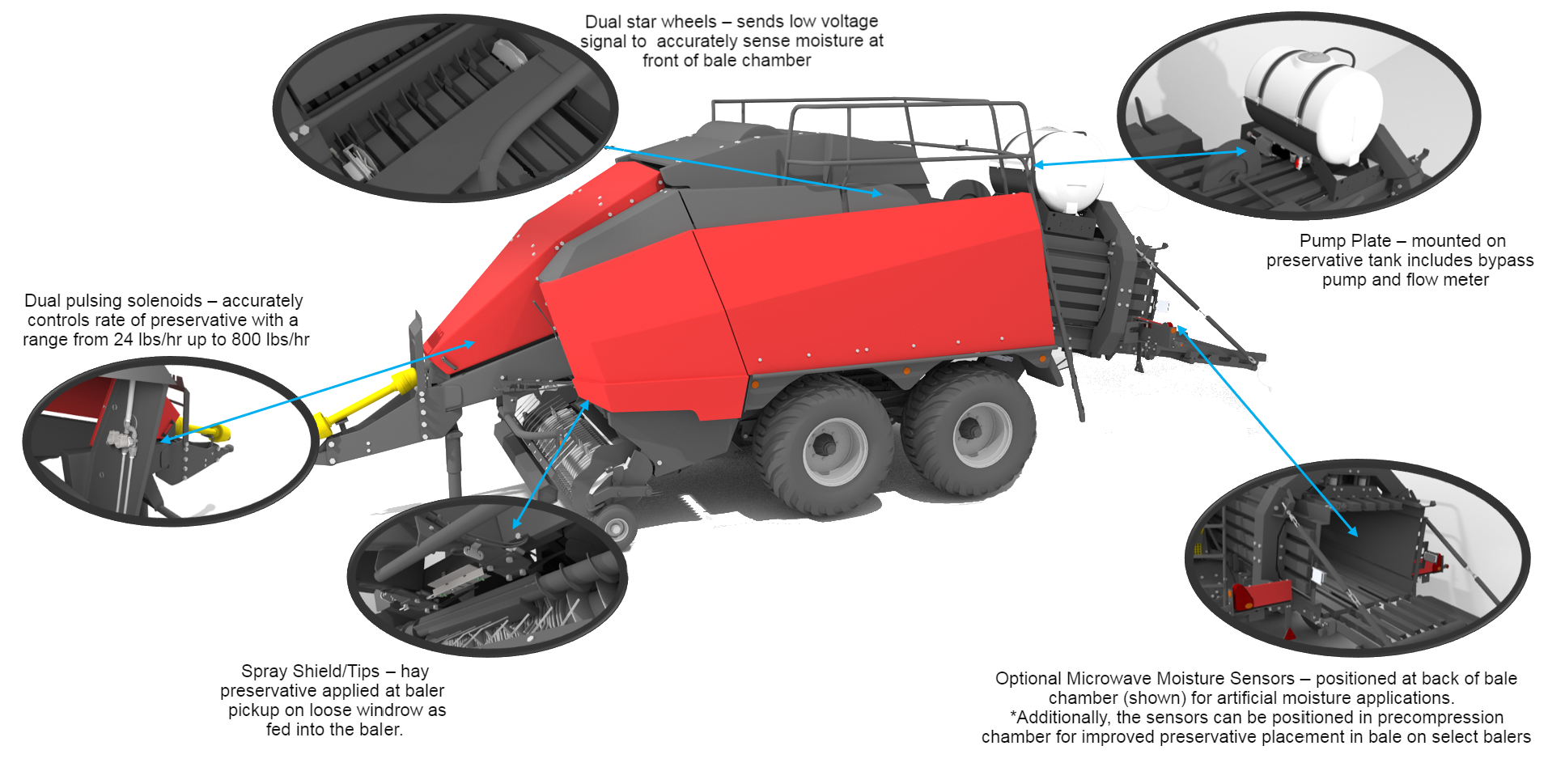

Large Square Baler Applicators

Introducing the New 700 Series Automatic Applicator for Large Square balers! This automatic applicator replaces the 600 series and will make adding preservative to your hay crop even easier and more efficient than ever before!Layout of the 700 Series Components

Key Design Improvements

- Single bypass pump supplying constant pressure to pulsating solenoid valves for improved response time to changes in moisture. This means no lag in preservative application while pump has to build up pressure - Improved flowmeter that works on a range of products - Display applicator readings on dedicated Virtual Terminal, Apple tablet, or Android tablet o Free Precision Baling App from Apple iTunes or Google Play store when using an approved tablet. Click here to see the control options and functions Same industry leading accuracy for the 700 Series Automatic Applicator

Using side-to-side moisture reading technology, the automatic applicator reads crop moisture across the width of the bale near the front of the chamber via moisture sensing dual star wheel sensors for large square balers. The sensor will read crop moisture from 5% up to 70% for those customers that make high moisture bales as well as dry bales.

Same industry leading accuracy for the 700 Series Automatic Applicator

Using side-to-side moisture reading technology, the automatic applicator reads crop moisture across the width of the bale near the front of the chamber via moisture sensing dual star wheel sensors for large square balers. The sensor will read crop moisture from 5% up to 70% for those customers that make high moisture bales as well as dry bales.

Key New Features of the 700 Series Automatic Applicator

| ▪ Single pump means less maintenance | ▪ More reliable baling rate generated from internal star wheel encoder |

| ▪ New style flow meter with improved reliability | ▪ Larger tips that prevent plugging at spray shield |

| ▪ Lower up-front cost on complete applicator | ▪ Superior sealing Deutch plugs throughout harnesses |

| ▪ Optional Harvest Tec dedicated monitor | ▪ Optional tablet monitor – use either Apple or Android approved devices |

| ▪ Update applicator settings while in operation | ▪ Reopen existing job record and add to it |

| ▪ Dual solenoids allow for large range of baling rates covered with each tip, and shuts product off to eliminate any dripping | |

Updates on the 700 Series System

Electronic Applicators (manual)

Operators that are interested in a more simplified system also have the option of an Electronic Applicators system for large square balers. Equipped with a high-capacity 115-gallon tank mounted on the rear of the baler, and a control box in the cab of the tractor. The operator is in complete control of the application adjustments 700 Series Automatic or Electronic

Comparison of Applicator Controls |

||

| Electronic Applicator | 700 Series Automatic | |

| Single Pump System | X | X |

| Control box with Adjustable Dial | X | |

| iPad Display | X | |

| Android Display | X | |

| ISOBUS Display | X | |

| Harvest Tec VT Display | X | |

| Automatic Application | X | |

| Moisture Sensing Capabilities | X | |

| Job Records | X | |

| Calculates Baling Rate | X | |

| Hay Indicator Compatible (Crop Eyes) | X | X |

| Dye Marker Compatible | X | |

| RFV Compatible | X | |

| Microwave Moisture Compatible | X | |

Applicators for Small Square Balers

Get started baling earlier and bale longer with the addition of a preservative application system to your small square baler. Systems are available as 55-gallon units and mount on the back frame of the baler. Choose between a new 300 series HayBoss automatic control system, a 600 series HayBoss G2 commercial automatic system, or an electronic or manual control system.

Get started baling earlier and bale longer with the addition of a preservative application system to your small square baler. Systems are available as 55-gallon units and mount on the back frame of the baler. Choose between a new 300 series HayBoss automatic control system, a 600 series HayBoss G2 commercial automatic system, or an electronic or manual control system.

Moisture Sensors for Small Square Balers

Automatic systems for small square balers are equipped with two star wheel moisture sensors mounted on the bottom of the bale chute, sensing moisture across the width of the bale via conductivity. The sensors can accurately read crop moisture from 8% to 60%, covering a wide range of moisture levels. As the star wheels turn, they also calculate tonnage, helping the system apply preservative even more accurately.Product Specs

All applicators come as complete kits designed to fit your specific baler, and consist of:- 55 gallon tank

- 12 volt pumping system

- All plumbing and wiring supplied

- Your choice of control options: 600 Series Automatic, new 300 Series Automatic, Electronic, or Manual

Comparison of Applicator Controls |

|||

| Electronic Applicator | 300 Series Automatic | 600 Series Automatic | |

| Single Pump System | X | X | |

| 3-Pump Manifold | X | ||

| Control Box with Adjustable Dial | X | ||

| iPad Display | X | X | |

| IOSBUS Display | X | ||

| Built-in Flowmeter | X | X | |

| Automatic Application | X | X | |

| Moisture Sensing Capability | X | X | |

| Job Records by Field | X | X | |

| Job Records by Individual Bales | X | ||

| Calculates Baling Rate: Round Baler | X | ||

| Calculates Baling Rate: Small Square Baler, Large Square Baler | X | X | |

| Export Job Records to iPad | X | ||

| Hay Indicator Compatible | X | X | X |

| Stroke Counter on Small Square Baler | X | ||

| Dye Sprayer Kit Compatible: Small Square Baler, Large Square Baler | X | ||

| Tagger Compatible: Large Square Baler | X | ||

Applicators for Round Balers

Hay preservative can be used to bale large round bales between 16% and 30% moisture. You have the option of a 25-gallon or, on certain models, a 55-gallon application system. The system mounts to the tongue of the baler and holds enough preservative to treat 30 to 60 tons of hay. Depending on your need, choose the new 300 series HayBoss automatic system, a 600 series HayBoss G2 commercial automatic system, an electronic system, or an economical manual control system (available in 25-gallon only).

Hay preservative can be used to bale large round bales between 16% and 30% moisture. You have the option of a 25-gallon or, on certain models, a 55-gallon application system. The system mounts to the tongue of the baler and holds enough preservative to treat 30 to 60 tons of hay. Depending on your need, choose the new 300 series HayBoss automatic system, a 600 series HayBoss G2 commercial automatic system, an electronic system, or an economical manual control system (available in 25-gallon only).

Moisture Sensors for Round Balers

Automatic systems for round balers are equipped with two moisture sensing discs, one mounted on each of the baler side walls, sensing moisture across the width of the bale via conductivity. The sensors can accurately read crop moisture from 8% to 60%, covering a wide range of moisture levels.

Moisture discs for round balers

Product Specs

All applicators come as complete kits designed to fit your specific baler, and consist of:- 25 or 55 gallon tank

- 12 volt pumping system

- All plumbing and wiring supplied

- Your choice of control options:600 Series Automatic, new 300 Series Automatic, Electronic, or Manual

Comparison of Applicator Controls |

|||

| Electronic Applicator | 300 Series Automatic | 600 Series Automatic | |

| Single Pump System | X | X | |

| 3-Pump Manifold | X | ||

| Control Box with Adjustable Dial | X | ||

| iPad Display | X | X | |

| IOSBUS Display | X | ||

| Built-in Flowmeter | X | X | |

| Automatic Application | X | X | |

| Moisture Sensing Capability | X | X | |

| Job Records by Field | X | X | |

| Job Records by Individual Bales | X | ||

| Calculates Baling Rate: Round Baler | X | ||

| Calculates Baling Rate: Small Square Baler, Large Square Baler | X | X | |

| Export Job Records to iPad | X | ||

| Hay Indicator Compatible | X | X | X |

| Stroke Counter on Small Square Baler | X | ||

| Dye Sprayer Kit Compatible: Small Square Baler, Large Square Baler | X | ||

| Tagger Compatible: Large Square Baler | X | ||

600 Series Automatic Control System

Large Square Balers

The 600 Automatic Applicator control system is the premier applicator for large square balers. The 600 system accurately senses moisture on-the-go and adjusts the application of preservative every three seconds to match the condition of the hay. This precision gives the operator the exact amount of product required to keep the crop in great condition, without wasting product. The all new 600 automatic system for large square balers can be controlled through the baler ISOBUS display or iPad, giving complete control to the operator more efficiently as ever without the need for a separate monitor in the cab. The display shows moisture content, speed of baling, and how much preservative is being applied. This control adjusts application rate every three seconds to attain the target rate.

This kit can be controlled one of three ways:

- If the baler is ISOBUS compatible, the applicator can be integrated and displayed through the baler monitor in the cab- no other display is needed.

- If the operator has an ISOBUS tractor with a VT display and is not using it to control the baler, the applicator functions can be viewed through the tractor display.

- If the ISOBUS options are not available, a Bluetooth receiver can be used to display the applicator through an iPad.

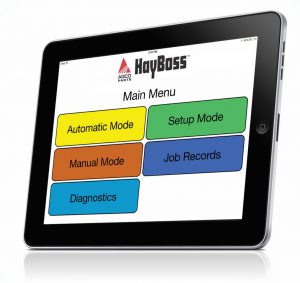

A simple push on the Main Menu key pulls up a selection of other screens including the adjustable settings and a Job Record screen. The system stores up to 300 job records by field, including date and time of baling, number of tons baled, product used and the average moisture and high moisture. The system will also store up to 33,000 individual bale records within those job records, and all of the job records can be exported to the iPad, or downloaded and printed via a USB port on the processor for easy and efficient access to crucial bale information.

The new Dye Sprayer Marking Kit that is found on large square balers can now be used on small square balers, allowing the operator to visibly mark the wet bales. GPS systems and bale scale kits can also be used with the 600 Series Automatic Applicator, helping the baling operation become more advanced and efficient than ever before.

Round and Small Square Balers

The 600 Automatic Applicator is the choice of applicator for the round or small square operator that makes hay commercially or is looking for the added performance and capabilities of the 600 system. On small square balers, the 600 system reads the moisture and tonnage with two star wheel sensors, and also has a stroke counter that records the number of strokes per bale, and an end of bale sensor, to record individual bale information like the large square system does.

The 600 system on round balers reads moisture with two discs in the bale chamber up to 70% moisture, and also has a sensor on the bale door to record individual bale records. Both systems have the ability to store and download job and individual bale records via USB and export via iPad.

300 Series Automatic Control System

Round and Small Square Balers

The 300 series automatic control system is a more compact and efficient applicator that accurately senses moisture on the go and adjusts the application of preservative to match the condition of the hay. This precision give the operator the exact amount of product required to keep their crop in great condition, without wasting product. The 300 Series applicator is controlled with an iPad* through a Bluetooth receiver, eliminating harnesses in the cab.

The 300 series automatic control system is a more compact and efficient applicator that accurately senses moisture on the go and adjusts the application of preservative to match the condition of the hay. This precision give the operator the exact amount of product required to keep their crop in great condition, without wasting product. The 300 Series applicator is controlled with an iPad* through a Bluetooth receiver, eliminating harnesses in the cab.

New improvements to the 300 Series Automatic Applicator include:

- Single constant-pressure pump with pulsing solenoid that reacts quickly to changes in application rates

- Improved flowmeter that works on a range of products

- Smaller and more compact system that is easier to install and maintain

The applicator takes moisture and baling rate information from the two star wheel sensors on small square balers, and two moisture discs in the bale chamber on round balers, and the system will automatically apply the correct amount of product. The moisture, tonnage, and rates are all displayed on the screen, along with the volume used. A simple push of any Main Menu key pulls up a selection of other screens including adjustable settings and a Job Records screen. The system stores 63 jobs by date and time, number of tons baled, product used, and high and average moisture.

*iPad Mini or iPad 3rd Generation (2012) or newer, running the current iOS operating system or one previous version required for iPad option

Electronic Control Systems

The electronic cab control is a solid state electronic pump control used for large round and large square balers. The control is mounted in the cab or on the fender. Application rate is quickly and easily adjusted from the operator s seat. Once set, the electronic control will hold the application rate constant. This unit is included with all 25-and 55-gallon applicators with electronic control. It is also included with 100-gallon applicators with electronic control for large square balers.

The electronic cab control is a solid state electronic pump control used for large round and large square balers. The control is mounted in the cab or on the fender. Application rate is quickly and easily adjusted from the operator s seat. Once set, the electronic control will hold the application rate constant. This unit is included with all 25-and 55-gallon applicators with electronic control. It is also included with 100-gallon applicators with electronic control for large square balers.

Manual Control Systems

The manual pressure regulator provides full-rate adjustment at the applicator, which is controlled on the baler. This economical control is available for 25-gallon applicators only. *There is no regulation control in the cab of the tractor with this unit.

The manual pressure regulator provides full-rate adjustment at the applicator, which is controlled on the baler. This economical control is available for 25-gallon applicators only. *There is no regulation control in the cab of the tractor with this unit.

Your hay is important. Make sure your preservative does what it says it will.

Shut - Off Eye Kit

Part No. HT474A The shut-off eye senses hay on the balers pick-up automatically, starting and stopping the application.HT474A Shut-Off Eye Kit for use with 464 Automatic Control, 2005 & newer Automatic & Electronic Controls

iPad Mini Display Kit

Part No. H30-4670DK Order a iPad display kit to use with your Bluetooth receiver. Kit consists of Apple iPad Mini, protective case, mount, charger, and pre-loaded Hay App.

Flow Meter

Part No. HT453 Digital electronic flow meter for use with any preservative applicator delivering between 40 and 500 pounds per hour. The flow meter reads the application rate in pounds per hour and total pounds used.

H2O Precision Moisture Sensor

Part# HT200RB The H2O Precision Moisture Sensor is a new moisture option for round balers. Two discs that mount in the bale chamber read moisture with the patented side-to-side technology, allowing accurate readings up to 60% moisture for all hay types. The H2O Precision Moisture Sensor is controlled with your Apple or Android smart phone or tablet via Bluetooth and free app.

Transfer Pumps

Transfer AGCO Hay Preservative safely and easily from your storage container to your applicator tank, use any of the following transfer pumps. Part No. HT9214: For a rapid transfer rate of 15 gallons per minute, this 12-volt unit can get the job done quickly.

Floor-Mounted Applicator Pause Switch

Part No. HT475 The floor-mounted applicator pause switch is an inexpensive addition to your application system that enables the operator to easily stop and start the applicator. For use with any HayBoss application system, 2005 and newer.

Dye Sprayer Marking System

Part No. HT0840 The Dye Sprayer Marking System is a simple way to visibly mark the wet areas on your large square bales. Compatible with the Model 696 Automatic Applicator, Model 600 Moisture Monitor for any large square baler, and 600 series automatic applicators for small square balers, the 3-gallon system is mounted near the bale chamber and when the adjustable high moisture alarm sounds, the system will spray a red-colored, food-grade dye on the exact location on the bale for a quick and easy reference.

Microwave Moisture Kit

Part No. HT700MWM Read your moisture accurately and quickly with microwave sensors that are located in the precompression chamber. Kit includes two sensors and harness. Part No. HT701MWM Microwave sensor kit for use with a steamer. Mounted in the back of the chamber, the sensors accurately read artificial moisture in the bale

GPS Interface Kit

Part # HT0880 By incorporating the GPS into the Model 600 Moisture Monitor, 696 Automatic Applicator, or HayBoss G2 Tagger, the producer has the ability to create yield maps for their crops, allowing them to gain the knowledge needed to maximize productivity. The kit consists of a removeable data storage card and GPS interface harness that is compatible with the Trimble 162 AgGPS, which is purchased separately from a Trimble dealer.AGCO Hay Preservative and Applicators

Challenger Hay Preservative Products Literature (French)

Preservative Treated Hay for Horses

MSDS for AGCO Buffered Acid Hay Preservative

MANUALS:

300 & 600 Series Automatic Applicator kits DO NOT include display

Made for iPad® (3rd through 2nd generation), running the currect iOS operating system or one version previous is required for iPad operation *iPad is a trademark of Apple Inc., registered in the U.S. and other countries.

*Contact Your Local AGCO Dealer For Pricing*

Click HERE for the complete list of applicators and AGCO part numbers

LARGE SQUARE BALERS - 110 GALLON APPLICATION SYSTEMS |

|||

| Baler Model | HayBoss G2™ Automatic Applicator | Electronic Control Applicator | Upgrade to HayBossG2™ |

| AGCO Balers | |||

| 7430 | HT6964494B | HT4914494 | HT6654494B |

| 7430 w/ RotoCut | HT6964500B | HT4914500 | HT6654500B |

| 7433, 7434, 7444, 2150, 2170, 2190 | HT6964518B | HT4914518 | HT6654518B |

| 7433, 7434, 7444, 2150, 2170, 2190 w/RotoCut | HT6964519B | HT4914519 | HT6654519B |

| Challenger Balers | |||

| LB 33 | HT6964494B | HT4914494 | HT6654494B |

| LB 33 w/RotoCut | HT6964500B | HT4914500 | HT6654500B |

| LB34 | HT6964492B | HT44914492 | HT6654492B |

| LB34 w/RotoCut | HT6964501B | HT4914501 | HT6654501B |

| LB33B, LB34B, LB34BXD, LB44B, 2250, 2270, 2270XD, 2290 | HT6964518B | HT4914518 | HT6654518B |

| LB33B, LB34B, 2250, 2270, 2290 w/RotoCut | HT6964519B | HT4914519 | HT6654519B |

| LB33B, 2250 w/PackerCut | HT6964527B | HT4914527 | HT6654527B |

| LB34B XD, 2270XD w/RotoCut | HT6964530B | HT4914530 | HT6654530B |

| 2370 UHD | HT6964544B | HT4914544 | HT6654544B |

| Hesston Balers | |||

| 4750, 4755 | HT6964490B | HT4914490 | HT6654490B |

| 4760 | HT6964494B | HT4914494 | HT6654494B |

| 4760 w/ RotoCut | HT6964500B | HT4914500 | HT6654500B |

| 4790 | HT6964492B | HT4914492 | HT6654492B |

| 4790 w/ RotoCut | HT6964501B | HT4914501 | HT6654501B |

| 4900, 4910 | HT6964491B | HT4914491 | HT6654491B |

| Massey Ferguson Balers | |||

| 2050 | HT6964494B | HT4914494 | HT6654494B |

| 2050 w/RotoCut | HT6964500B | HT4914500 | HT6654500B |

| 2140, 2150, 2160, 2170, 2170XD, 2190, 2250, 2270, 2270XD, 2290 | HT6964518B | HT4914518 | HT6654518B |

| 2140, 2150, 2160, 2170, 2190, 2250, 2270, 2290 w/RotoCut | HT6964519B | HT4914519 | HT6654519B |

| 2250, 2270, 2270XD w/ProCut | HT6964542B | HT4914542 | HT6654542B |

| 2150, 2250, w/PackerCut | HT6964527B | HT4914527 | HT6654527B |

| 2170XD, 2270XD, w/RotoCut | HT6964530B | HT4914530 | HT6654530B |

| 2370 UHD | HT6964544B | HT4914544 | HT6654544 |

SMALL SQUARE - 55 GALLON APPLICATION SYSTEMS |

|||||

| Baler Model | HayBoss G2™ Auto Applicator | 300 Series Auto Applicator | Electronic Control Applicator | Manual Control Applicator | Upgrade to 300 Automatic |

| AGCO Balers | |||||

| 7105, 7110, 7115, 7120 | HT6444416B | HT3444416C | HT4344416 | HT4324416 | HT3U44416C |

| 1835, 1837, 1839, 1841 | HT6444416B | HT3444416C | HT4344416 | HT4324416 | HT3U44416C |

| 1836, 1838, 1840, 1842 | HT6444416B | HT3444416C | HT4344416 | HT4324416 | HT3U44416C |

| 1843N, 1843S | HT6504502B | HT3504502C | HT4484502 | N/A | HT3U04502C |

| 1844N, 1844S | HT6504485B | HT3504485C | HT4484485 | N/A | HT3U04485C |

| Challenger Balers | |||||

| SB 34, 36, 44 | HT6504485B | HT3504485C | HT4484485 | HT4384485 | HT3U04485C |

ROUND BALERS - 25 GALLON APPLICATION SYSTEMS |

||||

| Baler Model | 300 Series Auto Applicator | Electronic Control Applicator | Manual Control Applicator | Upgrade to 300 Automatic |

| AGCO Balers | ||||

| 5134, 5145, 550 | HT3464484C | HT4414484 | HT4394484 | HT3U64484C |

| Challenger Balers | ||||

| RB 34, 44, 45, 42 | HT3464484C | HT4414484 | HT4394484 | HT3U64484C |

| Hesston Balers | ||||

| 500 Series: 530, 540, 545, 550, 555S, 555T, 560, 565A, 565T | HT3464484C | HT4414484 | HT4394484 | HT3U64484C |

| 814 Fixed Chamber | HT4414484 | HT4394484 | ||

| Massey Ferguson Balers | ||||

| 1734, 175, 1746, 1756 | HT3464484C | HT4414484 | HT4394484 | HT3U64484C |

ROUND BALERS - 20 GALLON APPLICATION SYSTEMS |

||||

| Massey Ferguson Balers | ||||

| 4100 Series | HT331 | HT431 | N/A | Contact Harvest Tec |

ROUND BALERS - 55 GALLON APPLICATION SYSTEMS |

||||

| Baler Model | HayBoss G2™ Auto Applicator | 300 Series Auto Applicator | Electronic Control Applicator | Upgrade to 300 Automatic |

| AGCO Balers | ||||

| 5446, 5446 Silage, 5456, 5545, 5545 Silage, 5546, 5546 Silage, 5556, 5556 Silage, 2745, 2746, 2746A, 2756A, 2766 | HT6494508B | HT3494508C | HT4484508 | HT3U94508C |

| 2846, 2846A, 2856, 2856A, 2946, 2946A, 2956, 2956A | HT6494524B | H449T4524B | HT4484524 | HT3U94524C |

| Challenger Balers | ||||

| RB453, 453A, 463, 463A, 563, 563A, RB56C, RB56CA | HT6494524B | HT3494524C | HT4484524 | HT3U94524C |

| Hesston Balers | ||||

| 800 Series - 845, 846A, 855, 856 | HT6494508B | HT3494508C | HT4484508 | HT3U94508C |

| 900 Series - 946, 955, 956 | HT6494508B | HT3494508C | HT4484508 | HT3U94508C |

| Massey Ferguson Balers | ||||

| 2745, 2746, 2746A, 2756A, 2766 | HT6494508B | HT3494508C | HT4484508 | HT3U94508C |

| 2846, 2846A, 2856, 2856A, 2946, 2946A, 2956, 2956A | HT6494524B | HT3494524C | HT4484524 | HT3U94524C |

MOISTURE ONLY SYSTEMS |

||

| Baler Style | Moisture Only | Upgrade to Auto Applicator |

| Small Square | HT201SS (H2O Kit) | N/A |

| HT600SS | Contact Harvest Tec | |

| Round Baler | HT201RB (H2O Kit) | N/A |

| HT600RB | Contact Harvest Tec | |

| Large Square | HT201LS (H2O Kit) | N/A |

| HT600A | Contact Harvest Tec | |

ACCESSORIES |

|

| Description | Part Number |

| 400 Series iPad Conversion Kit | HT4672B |

| 600 Series iPad Conversion Kit | HT6672C |

| iPad Mini Mounting Kit | HT2012MK |

| iPad Mini & Mounting Kit Combo | HT4670DK |

| Baler Mounted Moisture Tester | H8-FX2000 |

| Hay Indicators (Crop-Eyes) | HT474A |

| Dye Marking System | HT0840 |

| H2O Precision Moisture Kit Dye Marker | HT200DM |

| RFV Dye Marking System | HT845RFV |

| Microwave Moisture Kit (pre-compression chamber) | HT700MWM |

| Microwave Moisture Kit (end of baler chamber) | HT701MWM |

| 12V Electronic Transfer Pump (4 Gal/Min) | HT9212 |

| 12V Electronic Transfer Pump (15 Gal/Min) | HT9214 |

| 110V Electronic Transfer Pump (4 Gal/Min) | HT9215 |