Case IH ProRFV System

Advanced precision in the production of Large Square Bales

A new concept in the way that hay producers and operators test the quality of their hay is the Case IH ProRFV System. This upcoming season, growers will have the ability to determine the Relative Feed Value (RFV) of the hay on the go as they are baling, and store and download that value for future use. Tied in with the ProID Tagger, the hay producer has the ability to put that all-important RFV number on each and every bale, giving his buyer the feeder the accuracy needed to make an even more balanced ration.

Why RFV is important

Alfalfa and other hay crops can have feed values that vary drastically, and wide swings in quality can affect the amount of hay that needs to be fed, the production potential of that hay, and the amount of additional protein and energy needed to balance a ration.

How does it work?

The standard practice used to check hay quality used to be through random core sampling of bales. However, determining the quality of the hay, tracking those bales through the feeding process, and adjusting rations for the values thought to be in those bales is a significant challenge. The ProRFV system adds the precision required to learn and track those changes in quality. The ProRFV system is downloaded into the operators 600 Series Automatic Applicator or Moisture Only system. A sample is taken from the windrow right after the hay is cut, and sent into a lab. When the results come back the value is entered into the program on the baler display. When it’s time to bale, the program takes the weight from the scale and the moisture from the applicator system to calculate the dry matter density, giving the RFV for each and every bale. The RFV value is displayed on the monitor while baling, is stored in the job records, and can also be written to an RFID tag.

The standard practice used to check hay quality used to be through random core sampling of bales. However, determining the quality of the hay, tracking those bales through the feeding process, and adjusting rations for the values thought to be in those bales is a significant challenge. The ProRFV system adds the precision required to learn and track those changes in quality. The ProRFV system is downloaded into the operators 600 Series Automatic Applicator or Moisture Only system. A sample is taken from the windrow right after the hay is cut, and sent into a lab. When the results come back the value is entered into the program on the baler display. When it’s time to bale, the program takes the weight from the scale and the moisture from the applicator system to calculate the dry matter density, giving the RFV for each and every bale. The RFV value is displayed on the monitor while baling, is stored in the job records, and can also be written to an RFID tag.

Requirements to Measure RFV

- C696 Applicator or C600 Moisture Only System

- Bale Scale

- ProRFV software

Is it accurate?

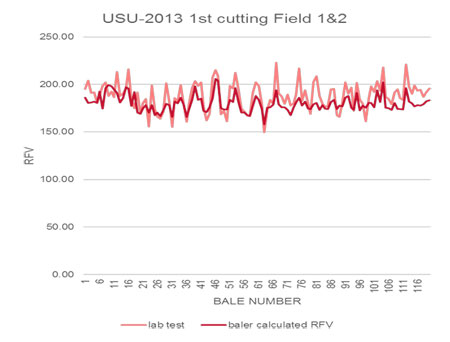

Within a study by Utah State University, the accuracy of the system has been tested during the 2013 on three cuttings covering four fields of alfalfa. The staff at USU cored 546 3×4 large square bales, sent the cored samples into a lab for NIR testing, and compared the cored values to the calculations made by the ProRFV system. An example of how the ProRFV system calculated RFV compared to the lab analysis of one example field can been seen in the graph below.  A complete copy of the study can be seen here: USU Final Report | Utah State final Study addendum

A complete copy of the study can be seen here: USU Final Report | Utah State final Study addendum

To verify the findings by Utah State, the ProRFV was installed on eight large square balers on alfalfa farms across six different states. Over 2000 bales were cored over various cuttings and conditions during 2013 and 2014. Listen to baler operator Don Leonard of Colorado explain the accuracy of the system.

The Full Potential

Identifying the quality in each bale

Now that the operator or grower has the capabilities to gather the all-important RFV number for each bale, the next step is applying those values to the bale as the bale goes from the field, to the stack, and to the feeder. This step consists of identifying each bale by RFV, and then sorting those bales accordingly based on quality.

The two common methods of identifying the individual bales are the RFV Dye Marker, and the ProID Tagger.

RFV Dye Marker

The RFV Dye Marker is a simple and economical add-on kit that marks each bale with 1, 2, or 3 stripes depending on the RFV range. The kit includes a tank, pump, plumbing, and spray nozzles. The spray nozzles are located at the back of the bale chute, and mark the bales with a blue food-grade dye for easy identification in the field.

ProID Tagger

The ProID Tagger is the premier method of identifying each individual bale. The Tagger applies a vinyl RFID tag on each bale, that holds all the crucial info for that bale: weight, moisture, preservative used, and of course RFV.

ProID Tagger mounted on the bale chamber

RFID tag on bale

Microchip inside of vinyl tag

The data is then read back with a hand scanner, loader attachment, or a truck portal scanner.

Putting it all together

Farms using the new system can scan and sort the bales as they come out of the field, sorting them by RFV in different quality groups. Sorting can also be done when the hay is stacked, or when a truck is loaded, giving the producers and sellers the ability to give the buyer precisely the hay quality that they want.

Listen as David Sharp, from Arizona, talk about how he can see the value in using the ProRFV system to maximize his marketing and hay production

�

Operators are seeing the value of the ProRFV system and the new opportunities to market their hay. Randomly coring bales to determine the RFV is now old technology, and the Case IH ProRFV system is giving farmers the precision needed to determine and manage their hay quality from start to finish. This is a new innovation in production efficiency for the hay producer of tomorrow!

Benefits

For the Hay Producer

- Accurate moisture, weight, and Relative Feed Value (RFV) on the go

- Create consistent bale stacks when sorting bales by:

- Moisture

- RFV

- Field location

- Harvest date

- Accurate inventory control

- Quality control

For the Dairy Operator

- Detailed individual bale records by moisture, RFV, etc.

- Consistent quality of hay feed to herd

- Accurate rationing and feeding, giving increased milk output per head

- Increased profitability

For the Hay Broker

- Know what type and quality of hay you are buying, selling, loading, and shipping

- Detailed bale records that can be printed or emailed to customers

- Accurate inventory control

- Accurate quality control

Watch the full CaseIH ProRFV video here

For more information, please contact your local Case IH dealership